Delivery

350090010 Test and angle dial HSK50

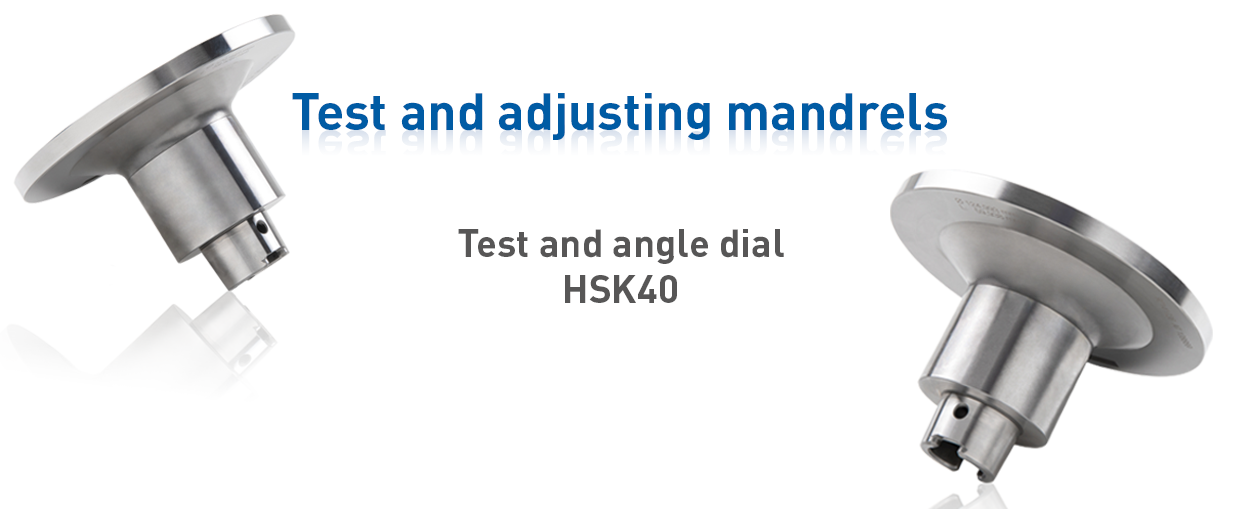

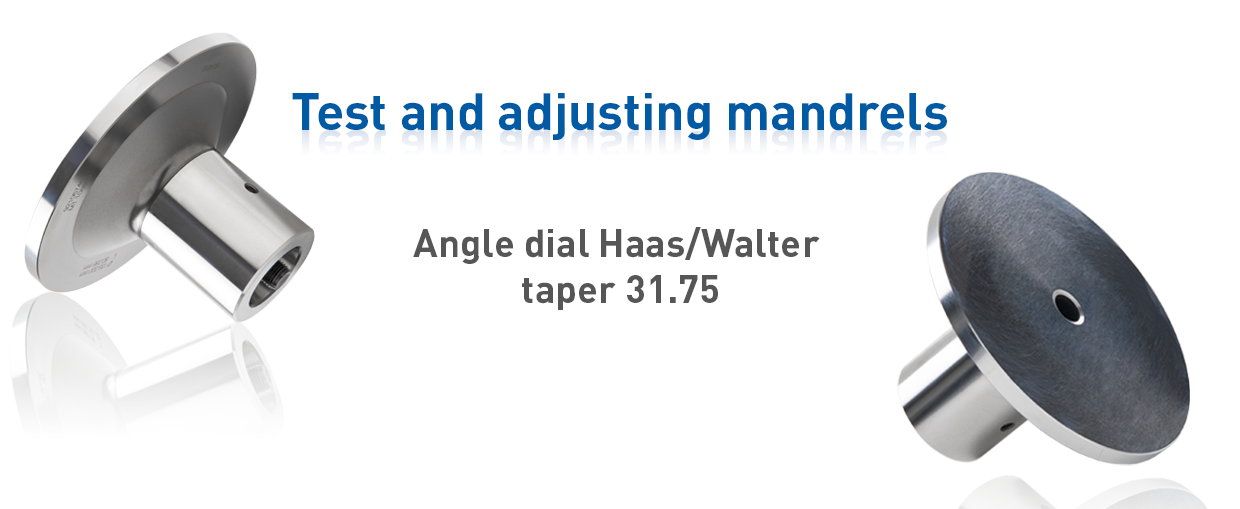

The test equipment and setting mandrels from GDS are primarily used for accuracy tests. They are also used for setting the machine axis and the presetting device. Because only with a perfectly adjusted machine will the result of its production be perfect.

Due to the precise manufacturing process at GDS, the direct concentricity deviation between the front part and the cone is a maximum of 2 µm. The enclosed data sheet and test report list the measured values. The length dimensions and the diameter are engraved on the gages. The measuring equipment is supplied in a high-quality wooden case.

350090010 Test and angle dial HSK50

350090020 Test and angle dial HSK40

350090030 Angle dial Haas/Walter taper 31.75

350090040 Test mandrel SK50 x ø50 x 200

350090050 Test mandrel HSK63 x ø50 x 200